Choosing the appropriate heat recovery unit to meet the specific requirements of the inwestor

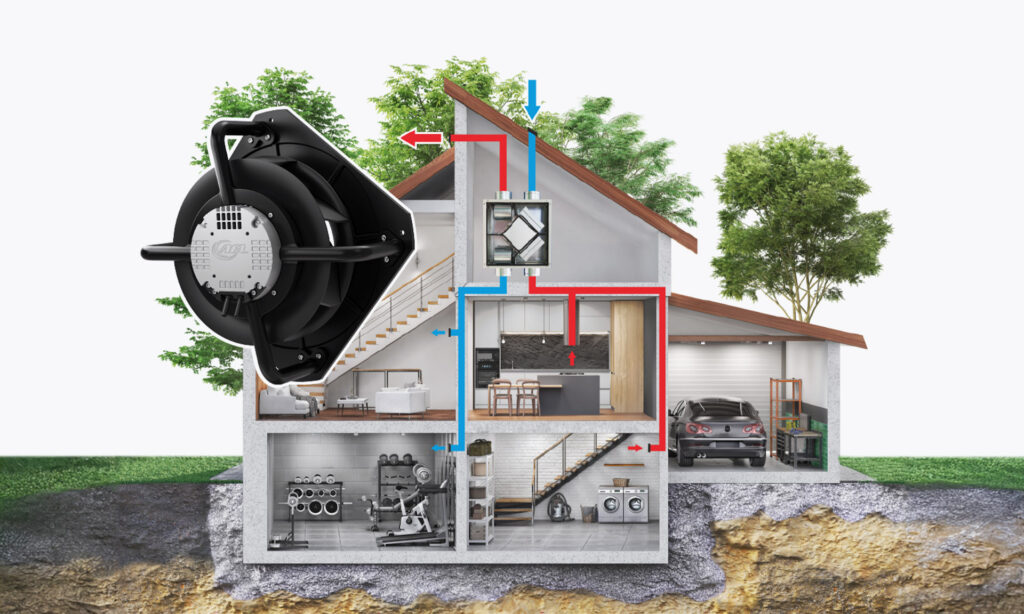

Since the beginning of the pandemic, there has been an increase in investor awareness regarding the air quality in enclosed spaces. What really matters is the thermal comfort and, most importantly, the quality of the air that residents breathe. If a building is too tightly sealed, it can lead to an increase in the concentration of pollutants in the room. Without efficient ventilation, the comfort of living in the building is compromised. Traditional gravity ventilation allows heat and air to escape outside, resulting in poor ventilation. As a result, many conscious investors opt for mechanical ventilation with heat recovery, and this is already taken into consideration during the building design stage. This ensures cost savings during the construction phase. There will be no need to construct ventilation chimneys, and the architect will be able to consider spaces for running ventilation ducts in such a way that their route is as straightforward and unobtrusive as possible. This solution will eliminate unnecessary airflow resistance and improve the efficiency of the installation.

PROPER VENTILATION

To ensure that the inhabitants of a house breathe fresh air, it is recommended to provide each person with at least 30 cubic meters of fresh air per hour. The ideal relative air humidity in a room during winter should be between 40-60%, while in summer, it should not exceed 70%. A well-designed and programmed heat recovery system helps in maintaining these parameters at the appropriate levels. It makes it easier to maintain the right temperature in the building, preventing the condensation of water vapor in cooler areas of rooms. A properly designed heat recovery system also allows you to regulate the intensity of its operation, depending on the individual needs of the house’s inhabitants. This is important because every ventilation system uses electricity, which costs money. The control system lets you take into account the absence of residents, temperature requirements at particular times of the day, and even increased demand for fresh air during a planned meeting with a larger group of friends.

WHAT IS A HRU?

A Heat Recovery Unit (HRU) is a type of ventilation unit commonly used to ventilate residential and small public buildings. It helps maintain air quality by removing stale air and supplying fresh air to the building. It also has filters to purify the air by removing harmful pollutants

One of the most important features of an HRU is its ability to recover the heat from the exhaust air and transfer it to the supply air. This helps to minimize heat loss during air exchange, which in turn reduces the cost of heating the building.

HOW DOES A HEAT RECOVERY UNIT WORK?

In the end, what matters the most for investors are the parameters that have been achieved, such as airflow, heat recovery efficiency, sound pressure level, and air filtration class. Therefore, it’s important to take a closer look at the basic components of air handling units that have a major impact on these parameters during their operation.

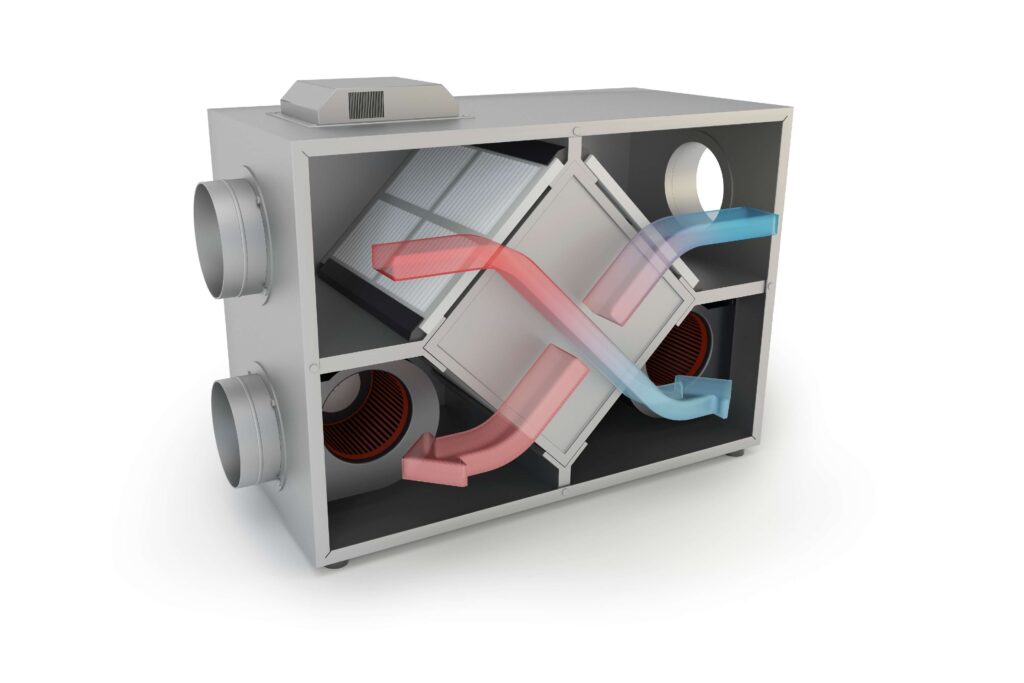

I. HEAT RECOVERY EXCHANGER

The effectiveness of the entire heat recovery system relies on the efficiency of the heat exchanger, which is the heart of the HRU. The structure of the heat exchanger plays a vital role in determining its effectiveness, including its type, shape, and material, as well as the method and accuracy of execution.

Three types of heat exchanger dominate the market:

- Cross-type – where the ducts with exhaust (warm) and supply (cold) air are arranged perpendicularly. They are simple to build, cheap and easy to clean. However, their efficiency is low – below 50-60%.

- Counter-current exchangers are similar to cross-flow exchangers but with supply and exhaust ducts arranged in parallel. The air flows in opposite directions, like in cross-flow exchangers, but the path is much longer, allowing for longer heat exchange. This results in an efficiency of heat recovery reaching over 90%. However, they have some disadvantages, such as increased flow resistance, difficulty in cleaning, and susceptibility to frosting with freezing condensate. Despite these issues, counter-current exchangers are currently the most popular type of exchanger due to their very high heat recovery efficiency, relatively small dimensions, and simple construction.

- Rotary heat exchangers have a cylinder shape with channels running parallel to their axis. Half of the cylinder is placed in the supply air stream, and the other half is placed in the exhaust air stream. The cylinder rotates, and exhaust air heats the exchanger, “regenerating” it, while supply air cools it. This allows exhaust and supply air to flow alternately through the same channels, making the principle of operation completely different from that of other exchangers. Efficiency can reach up to 90%. The greatest advantage of rotary heat exchangers is their complete resistance to frosting, even at extremely low temperatures, as the supplied air streams dry the ducts. That’s why they are popular in Scandinavia. However, their weakness is their tendency to mix the supply and exhaust air streams and the risk of failure of the rotating engine.

II. FANS

Two fans, supply and exhaust, move air in the heat recovery unit and the entire ventilation system. The size and power of these fans are adjusted based on the assumed airflow for the heat recovery unit. Each fan is also characterized by external static pressure, which refers to the airflow resistance in the ventilation system that the fan can overcome to blow a given amount of air.

Fans are one of the most important and expensive components of the air handling unit. They must provide adequate performance and pressure while being quiet, energy-efficient, and durable.

Fans can either be alternating current (AC) or electronically commutated, direct current (EC). AC fans are traditional and cheaper but have relatively low efficiency and slightly higher energy consumption. In contrast, EC fans are modern, energy-saving, and quiet, with smooth performance control. It is advisable to choose a control panel with EC fans because they offer some advantages to the user, such as:

- easy change of rotational speed from about 20% of the rated speed;

- lower energy consumption compared to regular AC fans,

- quiet operation.

III. FILTERS

The air that flows through the heat recovery unit is filtered initially, with rough filters installed on both the supply and exhaust sides. This helps prevent significant dirt buildup in the heat exchanger or ventilation ducts and ensures that the air supplied to the rooms is clean and free from major pollutants. To achieve accurate air filtration, filters with higher filtration efficiency, such as ePM10 or ePM2.5 (previously classified as F7 and F8), are often used.

SUMMARY

When purchasing a heat recovery unit, there are several factors to consider. Firstly, you can opt for units with a simpler structure and automation, which may cost less at the investment stage but could lead to higher operating costs. Alternatively, modern and technologically advanced HRU are fully automated and highly efficient in heat and moisture recovery. Although they are more expensive initially, they offer greater comfort of use and lower operating costs in the longer term. It’s important to check the components, including fans, that are built-in to ensure the device is energy-saving and quiet and not made with cheaper, lower-quality components.

If you’re interested in finding a list of HRU manufacturers that use AFL solutions, please contact our service office. We would be happy to recommend the best heat recovery units currently available on the market.

Author: Michał Paduch, Area Export Manager, AFL MOTORS

Suggested fan model

Based on the solutions discussed, we recommend this model B3P190-EC072-101