Air curtains are essential to modern environments such as shops, offices, and industrial halls. Their primary function is to create an air barrier that restricts heat exchange, protects against pollutants, and enhances user comfort. A crucial aspect of their operation is energy efficiency, which is becoming increasingly important given rising energy costs and the requirements associated with sustainable development.

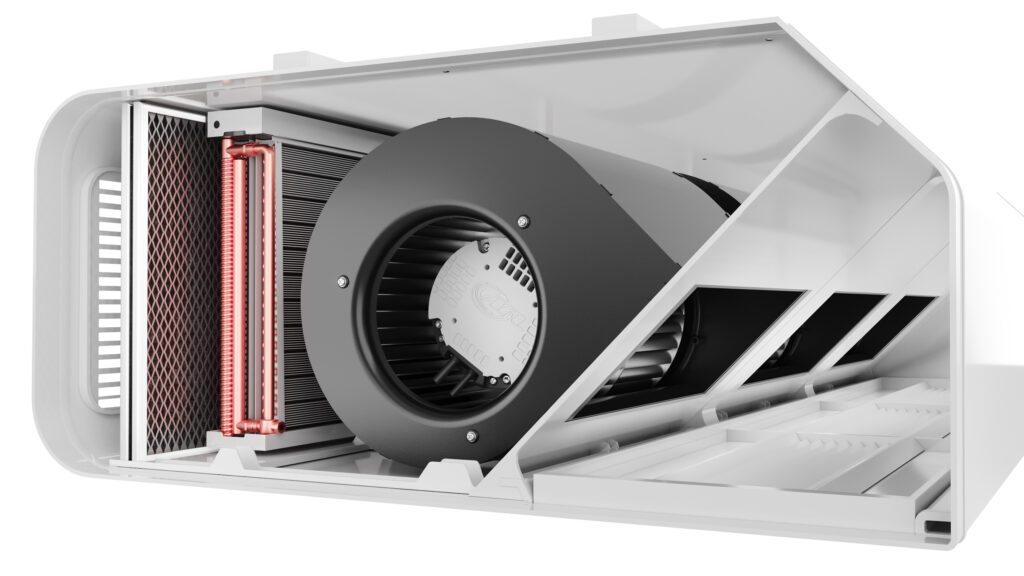

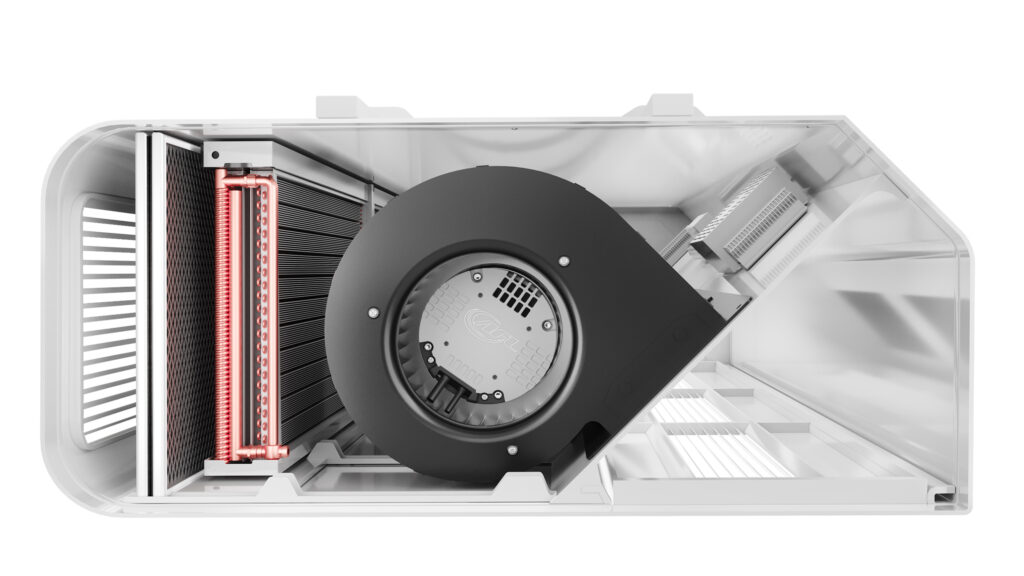

Achieving high energy efficiency is closely related to the device’s design, the use of modern technologies and the performance of key elements, such as the fans used, which ensure optimal airflow and minimise energy losses. Depending on the design of the device and the requirements of a given application, different types of fans are used. For example, axial fans are often used in industrial curtains with ample airflow, while budget solutions use longitudinal shafts mounted on motor shafts. However, the optimal solution for high-quality curtains is radial fans with rotors with forward-curved blades, colloquially called blowers. We will present this solution in more detail later in the article.

The role of blowers in air curtains

Fans, responsible for generating airflow, are the heart of the air curtain. If they are of low quality, they can significantly reduce the efficiency of air curtains. Uneven airflow reduces the effectiveness of the curtain, which translates into weaker protection against energy losses and pollutants entering the building. Additionally, such fans wear out faster, which leads to more frequent repairs and higher maintenance costs. Low-quality components can also increase energy consumption, raise bills, and negatively affect the environment. Moreover, the noise generated by such fans can be bothersome, especially in workplaces or public spaces where acoustic comfort is key.

Therefore, it is worth investing in high-quality components. Due to their operating characteristics, forward-curved radial fans are used in devices with high compression and quiet fan operation.

High-quality fans ensure optimal, balanced airflow at the appropriate speed, directly affecting the device’s effectiveness, providing protection against heat loss and the inflow of pollutants through the door opening. Thanks to modern technologies, such as EC motors, the blowers significantly reduce energy consumption, saving up to 50%.

At the same time, they are characterised by reliability and quiet operation, which guarantees acoustic comfort. Additionally, especially for applications in air curtains, AFL has developed EC motors with a quick start, allowing an immediate response to door opening.

Modern EC motors

EC motors are DC motors equipped with an electronic control system. Compared to traditional AC motors, they are much more efficient, reaching up to 90%. They enable precise control of the rotational speed, allowing for optimal air curtain operation adjustment to current needs. This allows EC motors to reduce energy consumption by 30-50% while limiting heat losses. Additionally, they are characterised by quiet operation, which significantly improves users’ acoustic comfort.

Airflow optimisation

Air curtain blowers are designed to make optimal use of electrical energy and generate a stable, balanced airflow. Innovations in this field include:

- Rotor profiling: Modern rotors with optimised blade shape minimise energy losses while generating a stronger and more even airflow.

- Variable speed technology: EC motors with smooth performance control, combined with algorithms in the curtain controller, allow the blower speed to be adjusted depending on external conditions (e.g., temperature differences), allowing for energy savings while maintaining efficiency.

- Minimizing air resistance: Blower housings are designed to reduce turbulence and dynamic losses, which translates into lower energy demand.

Automation systems

The basic mode of operation used in curtains is to switch it on when the door opens.

Advanced automation systems allow for increased energy efficiency of curtains by dynamically adjusting their operation to current conditions. In addition, they can also control the level of contamination of filters or the operation of elements such as heat exchangers. For example, additional temperature sensors enable automatic regulation of the intensity of the curtain’s operation depending on the temperature difference between the interior of the building and the surroundings. Integration with building management systems (BMS) allows for central control of the operation of air curtains, which optimizes their operation depending on the energy load and time of day.

Summary

Blowers in air curtains are responsible for their basic operation and significantly affect the energy efficiency of the entire system. Modern technologies, such as EC motors, optimized rotors, or advanced control systems, allow for achieving the highest level of efficiency and user comfort. Investing in advanced technological solutions for blowers is a step towards sustainable and economical energy management and high comfort of use.

Advantages of F3P146-EC092-608 blowers with quick start dedicated to air curtains

The quick start of the air curtains is key to their efficiency and functionality. Manufacturers emphasise that the curtain’s immediate activation when the door is opened minimises energy losses, maintains a stable indoor climate, and increases user comfort.

- Energy savings:The immediate creation of an air barrier prevents uncontrolled air exchange between the interior and the environment, which reduces the load on heating and cooling systems.

- Thermal comfort: The curtain’s rapid operation maintains the desired temperature inside the room, protecting against drafts and sudden temperature changes.

- Hygiene and cleanliness: After opening the door, an effective air barrier immediately prevents dust, dirt, and insects from entering the interior.

- Parameter stability: Thanks to the “constant flow” algorithm, we can maintain a constant airflow regardless of changing operating conditions (e.g., increased filter resistance).

AFL Motors has designed fans with EC motors specifically for use in air curtains. The fans enable energy-efficient use, and thanks to advanced components and a unique algorithm, the fan reaches full speed in just 𝟮 seconds!

Author: Grzegorz Perestaj, Regional Sales Director, AFL MOTORS