Client profile and area of operation

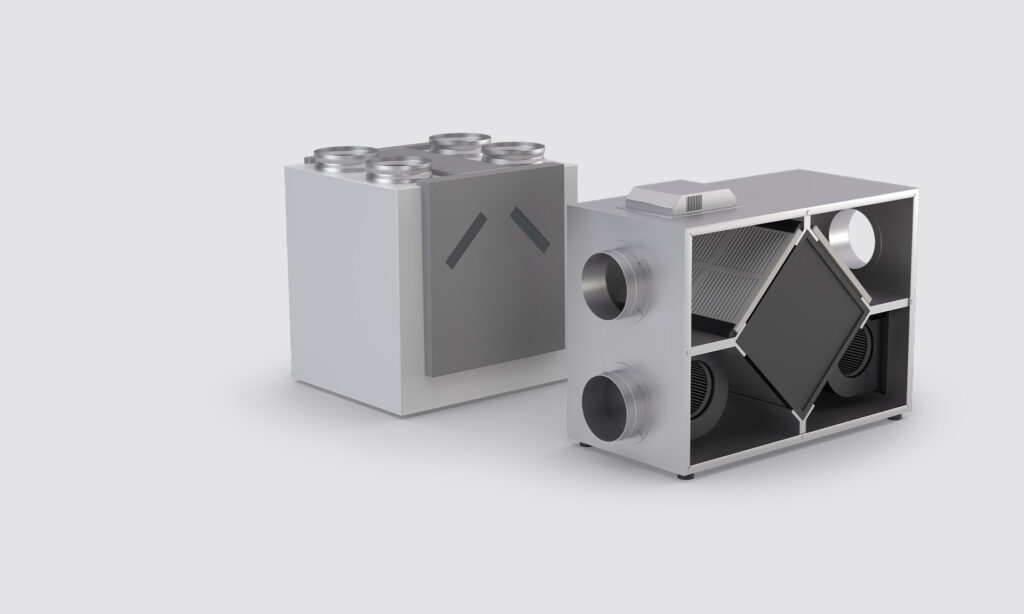

The client is a Czech manufacturer operating in the HVAC industry, specializing in heating and ventilation. Initially focused solely on the local market, the company has recently started expanding into European markets. The company primarily produces heat recovery units, which make up the majority of its product range.

The company’s dynamic growth, driven by innovative solutions and consistent sales increases, has created a need for a more flexible technology partner.

Challenges the company encountered and the need for change

The manufacturer looked for a solution that would allow the implementation of a heat recovery unit project with a dedicated fan, specifically designed to meet specific technical requirements.

Past experiences with fan suppliers from both the Far East and Europe were positive. However, over time, issues such as delivery flexibility, minimum order quantities (like the need to order full containers), and the inability to customize products to meet individual needs emerged.

Customizing the fan to the customer’s specifications became a major challenge, as the current supplier was unable to make the necessary design changes.

Expectations for AFL Motors Europe

The client outlined specific requirements for collaboration with AFL Motors Europe:

- Rapid prototype development according to the project schedule.

- Precise adjustment of the fan’s technical parameters (performance, noise level, power consumption, efficiency).

- Competitive pricing.

- Flexible logistics and on-time order fulfillment.

Collaboration process and solution

To ensure efficient project implementation, a clear timeline was established:

- Detailed guidelines were created regarding the operating parameters and dimensions of the fan.

- A maximum delivery deadline of 8 weeks was set for the first prototype.

- Within a week, the client conducted sample tests in their laboratory, providing feedback on power consumption and the operation of the fault signal. Our engineers from the Gdynia office also attended the tests.

- After the meeting, AFL engineers modified the motor design, including the magnet system, and updated the software.

- The second version of the prototype was delivered after 5 weeks.

- After minor wiring adjustments, version “2” was approved, and the client ordered a trial batch to verify the repeatability of parameters and build quality.

- After approving the trial batch, we started mass production and collaboration.

The project took approximately 8 to 9 months to complete.

Key benefits for the client

• Customization of the solution

The fan, designed from scratch, was perfectly suited to the application’s needs. The project was finished quickly while maintaining high quality and full technical compliance.

• No complaints

Over the three years of cooperation, there were no complaints despite the large volume of fans delivered. The logistics OTIF (On Time in Full) rate consistently remains at 90%. Each delivery was complete, exactly as ordered, with correct products, quantities, and quality. Only two deliveries were late, caused by disruptions in maritime transport, including vessel delays at transshipment ports and longer customs clearance times. The remaining deliveries were on time and complete.

• Logistics Optimization

Thanks to our partnership with AFL Motors Europe, the client was able to place smaller orders without needing to fill containers – a standard practice for imports from Asia. Additionally, the company kept a safety stock in Poland, which simplified order fulfillment and improved the client’s financial liquidity.

Customer feedback and factory tours

The client greatly valued the technical support and direct contact with the AFL office in Poland. They also appreciated the partnership-oriented approach and flexibility in order fulfillment.

„It was truly a pleasure to see your well-organised production, development, and measurement laboratory. I am confident that we now have a strong plan in place for the next phase of development, and that our cooperation will continue to grow significantly.”

— CEO of the Czech manufacturer

A visit by Czech representatives of the client and the company’s distributor to the AFL factory in China confirmed the high organizational standards, transparent processes, and modern technological facilities.

“This meeting with AFL has significantly increased our confidence in your company. Together, we have the opportunity to grow and develop strategic innovation projects that will drive the future of both our companies.”

— Industrial Manager, International distributor

Future of collaboration

The relationship is developing dynamically – preparations are currently in progress to make small but important changes to the fan’s design. Their aim is to further optimize the production process and enhance the device’s operational efficiency. Both parties plan to continue collaborating on projects and strengthen their engineering and business partnership.