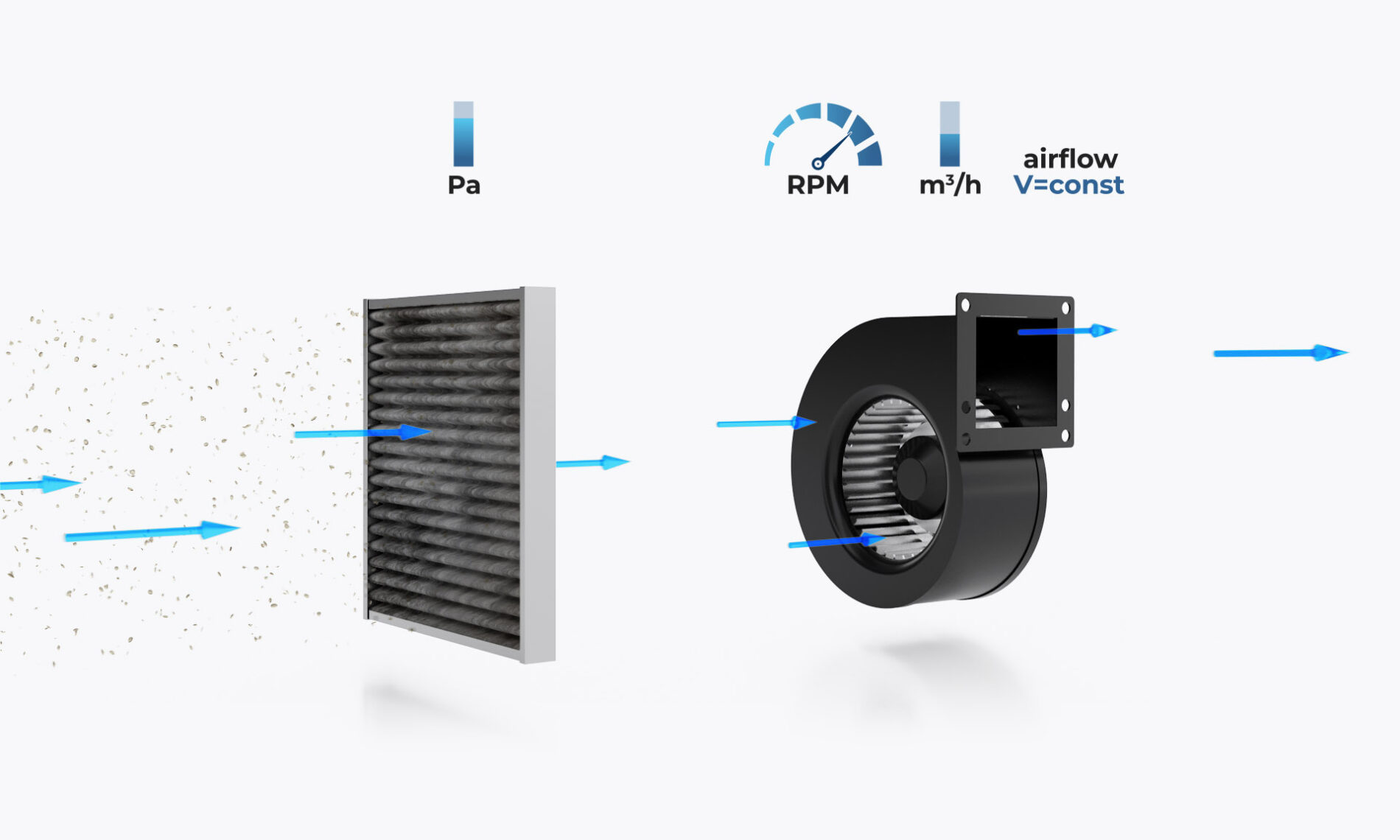

Ventilation systems and equipment are often designed to balance room inflow and exhaust air streams. This achieves the highest system efficiency and high heat recovery efficiency. However, during operation, the characteristics of the ventilation system continuously change, resulting in changes in airflow resistance.

These changes can be caused by factors such as the accumulation of contaminants on filters, condensation of water vapor in the heat exchanger, or changes in air temperature.

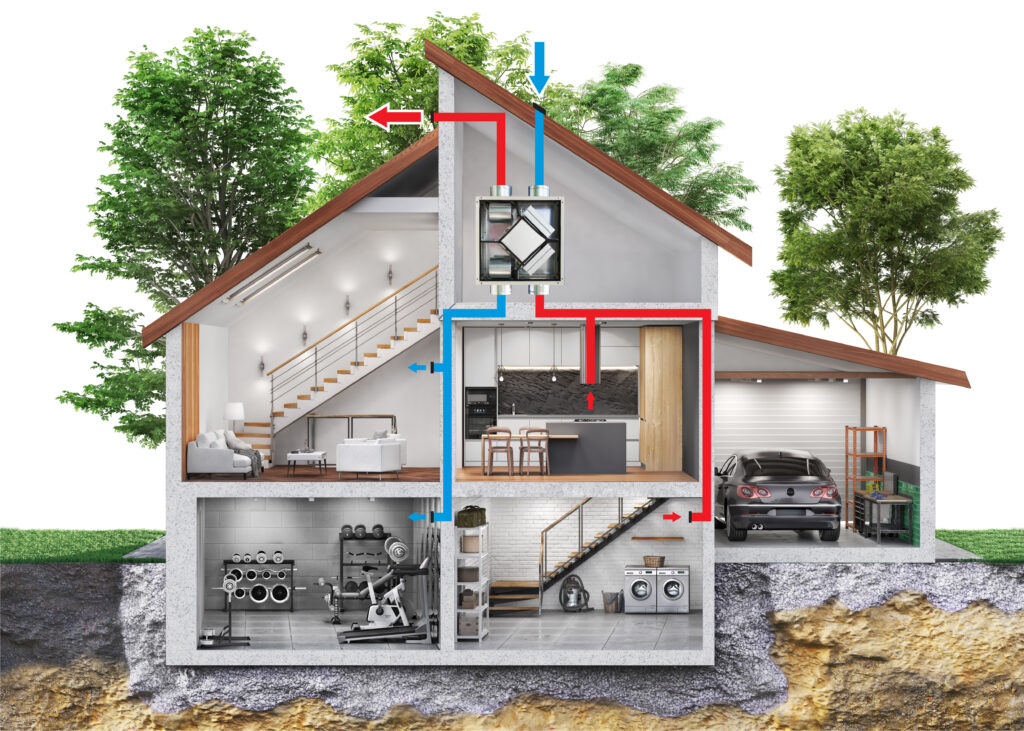

Balanced mechanical ventilation with heat recovery is increasingly important in new buildings and renovated facilities due to its significant potential for energy savings and ensuring high indoor air quality.

Suppose the ventilation system operates in an unbalanced state. In that case, heat losses due to ventilation will increase because some air (due to overpressure or underpressure) enters the building through leaks in the external partitions, bypassing the heat recovery system.

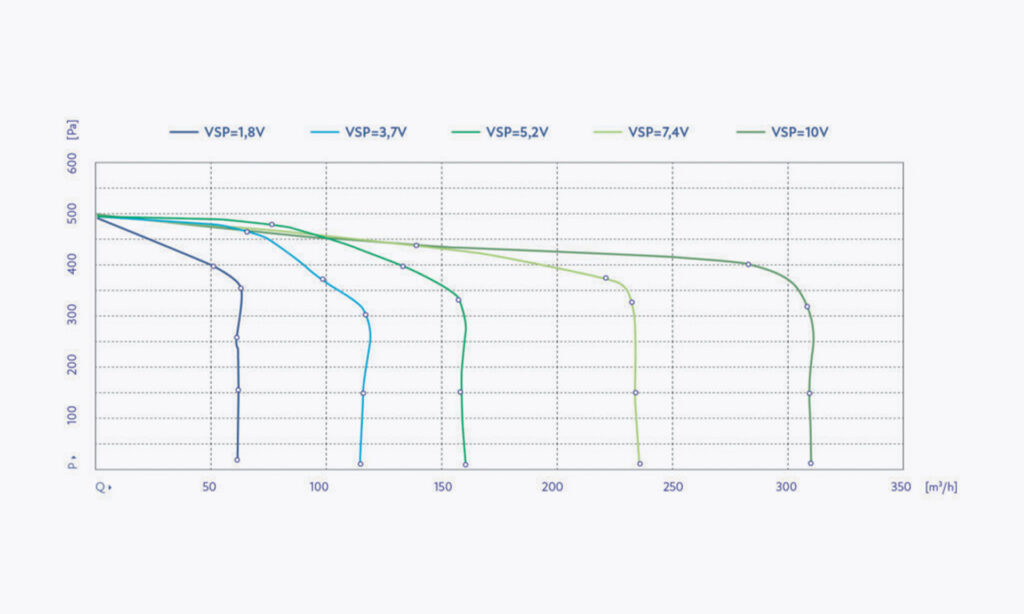

Large ventilation units are typically equipped with control systems that adjust the volume flow based on the effective pressure measurement at the fan inlet. This method allows for high accuracy in regulating fan performance and entire ventilation systems.

Today, even smaller ventilation devices, such as heat recovery units, are increasingly being equipped by manufacturers with automatic flow balancing systems. These systems require additional pressure measurement sensors and control systems, which increases production costs.

However, there are fans on the market with Constant Flow control, which, thanks to built-in automation, maintains a constant flow rate despite changing resistances.

AFL, a manufacturer of energy-efficient fans with EC motors, has introduced a series of forward-curved radial fans with Constant Flow-type blades into its product range. These are selected models with a single inlet from the F3P series.

This solution also significantly improves comfort during operation. The fan automatically reduces its rotational speed at low airflow resistances, greatly reducing power consumption and noise.

An additional advantage is that the Constant Flow operating characteristic is maintained throughout the entire range of fan speed regulation. This allows for easy adjustment of the amount of air delivered by the fan to changing needs.

The animation illustrates the concept of built-in Constant Flow control:

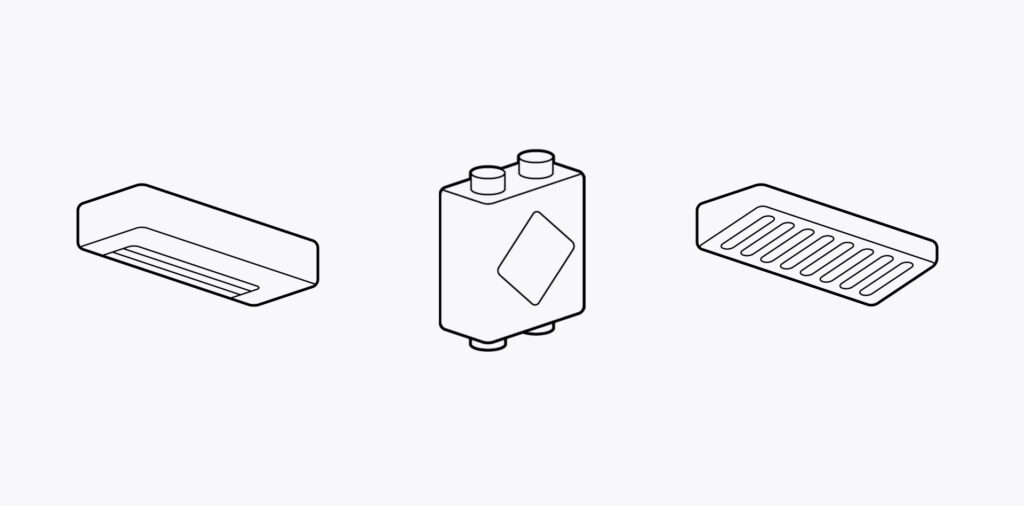

Due to their operating characteristics, forward-curved blade radial fans are used in devices where high pressure, a compact design, and quiet operation are required. They perform excellently in devices such as air curtains, heat recovery units, and kitchen hoods.

We invite you to explore our range of forward-curved blade radial fans with Constant Flow technology.

Author: Marek Skarżyński, Technical Support Manager, AFL MOTORS