Industrial fans are essential to your product

We are the European Sales and Technical Support Office for AFL MOTORS, a global manufacturer of industrial fans. We are committed to a partnership approach in every cooperation stage. We will back you up!

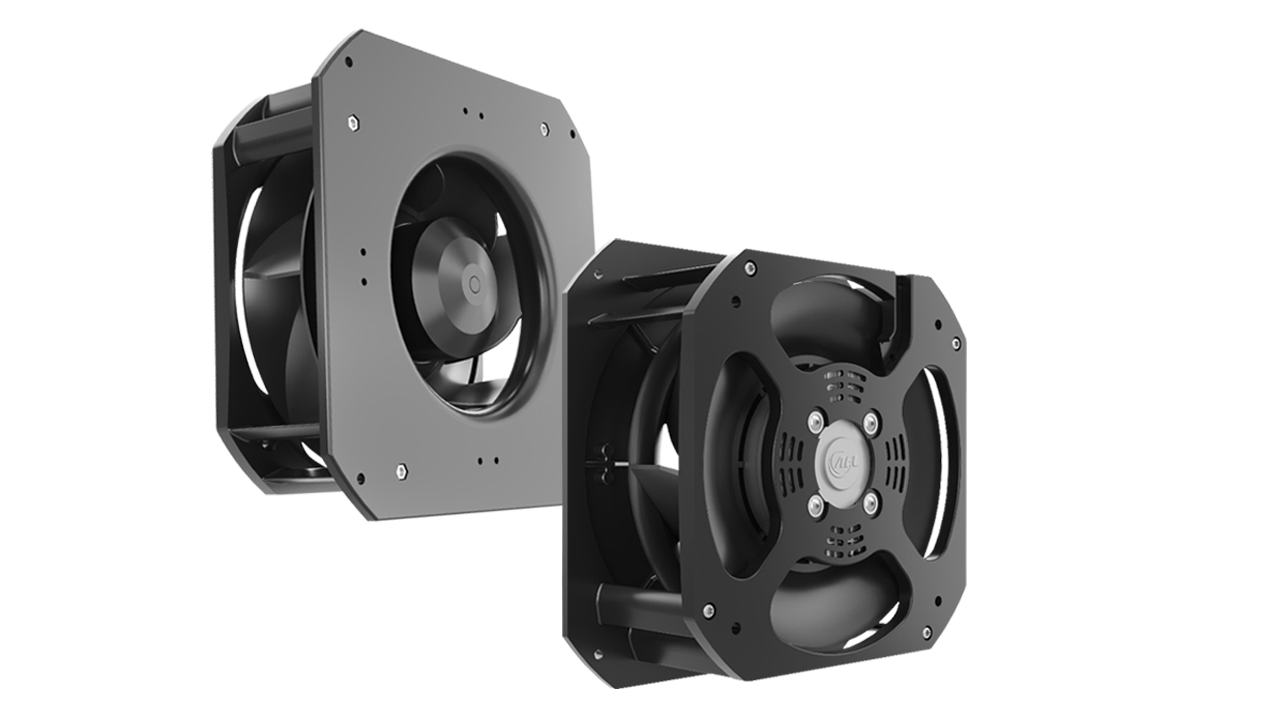

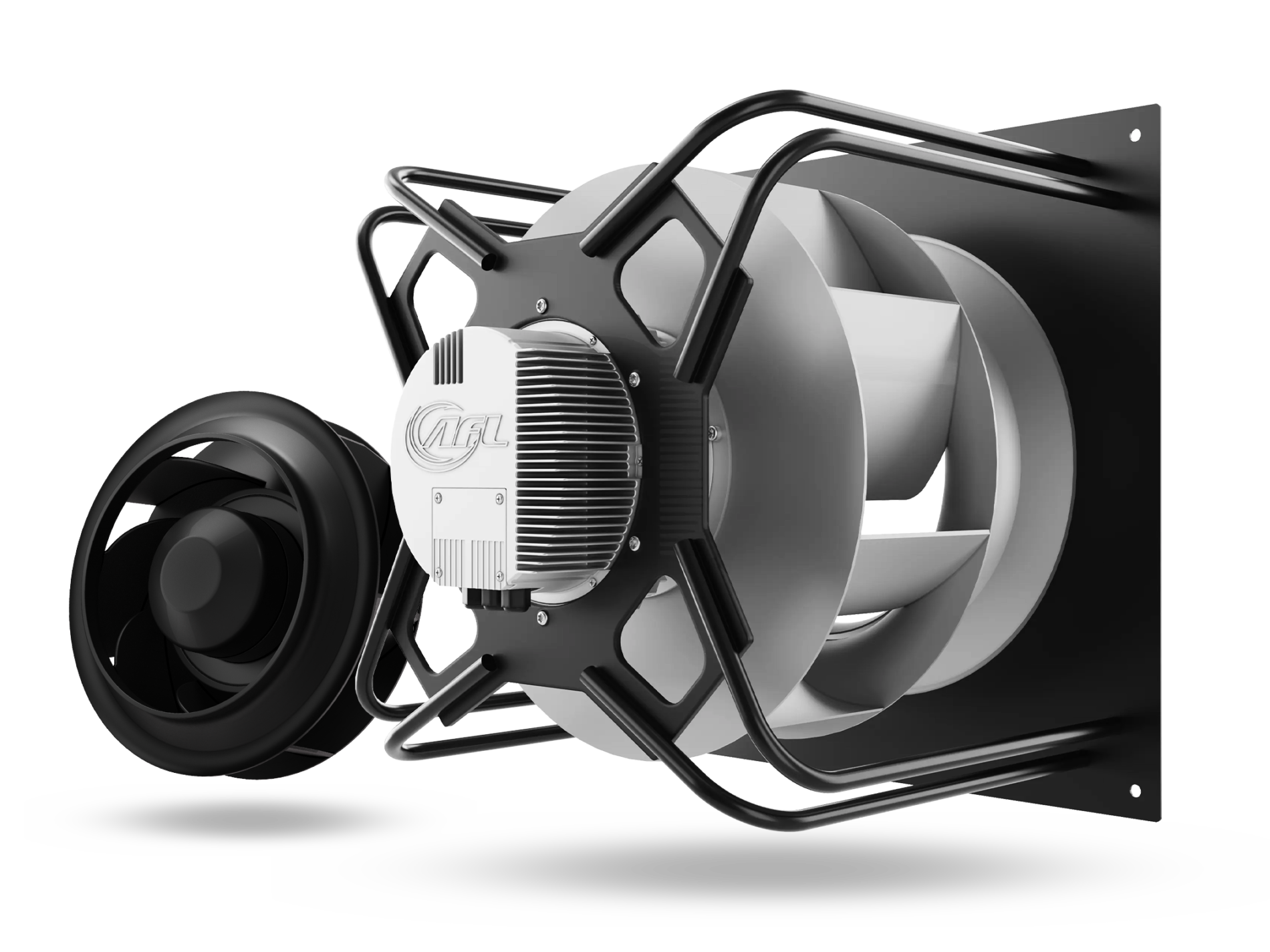

Introducing the new compact

centrifugal fans, model B3P190

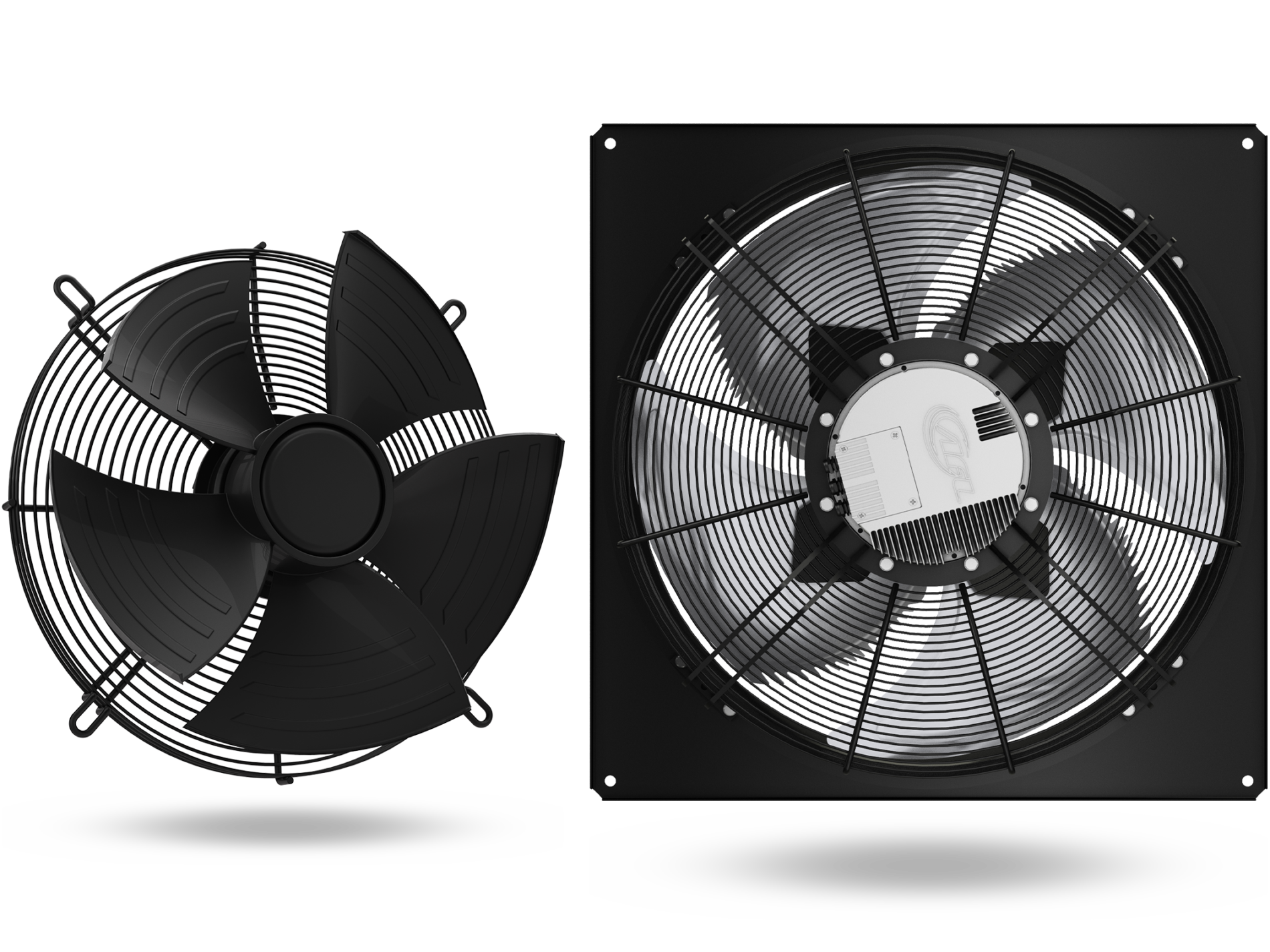

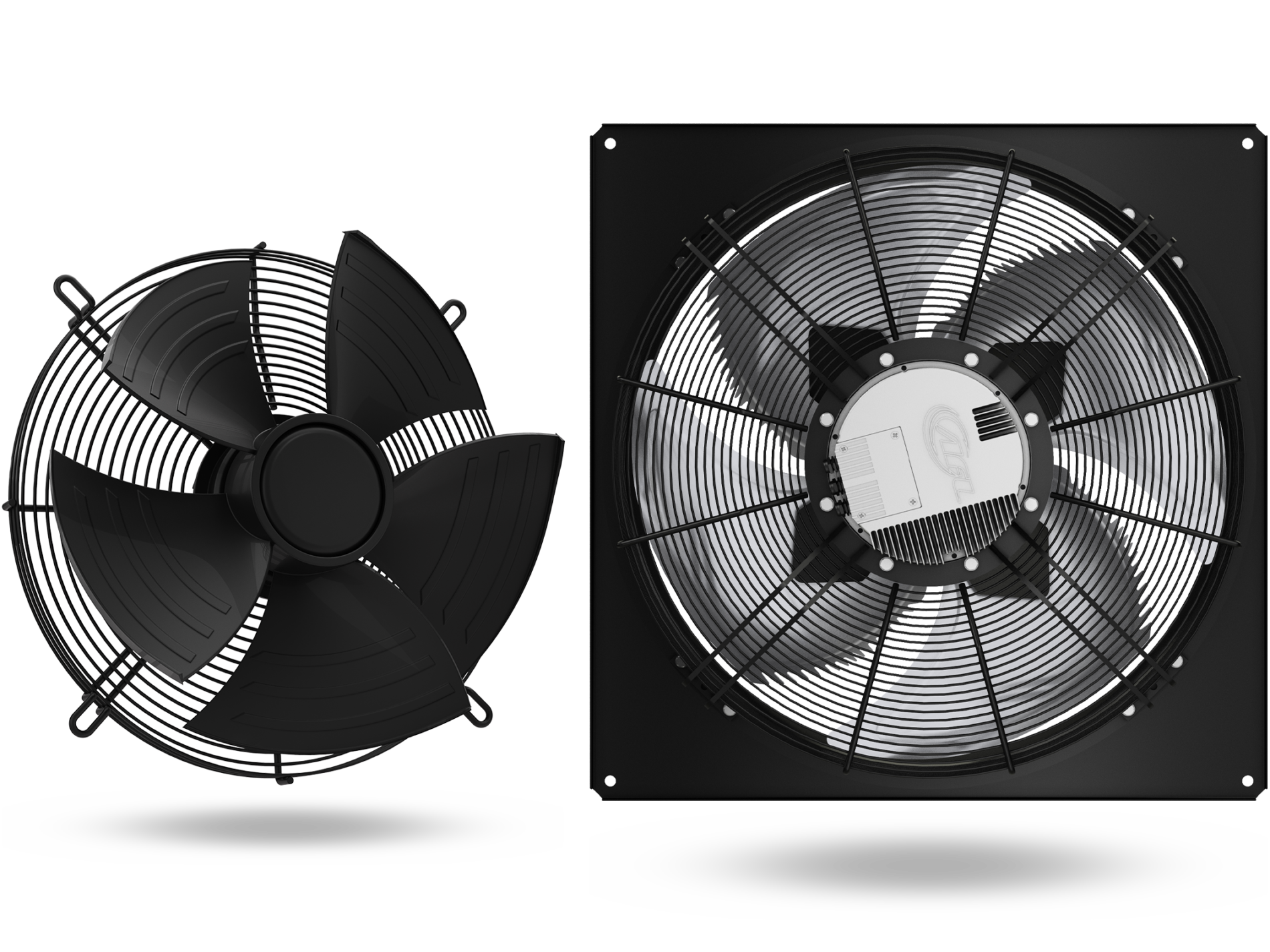

Backward curved centrifugal fans

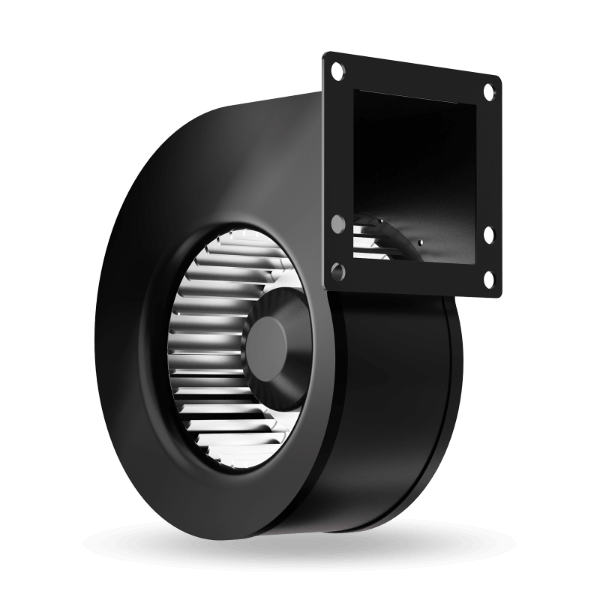

Single inlet forward curved centrifugal fans

Double inlet forward curved centrifugal fans

Select type

Please specify the type of industrial fan you need for your product

Select type

Input parameters

Search results

How do we operate?

Focus on quality, processes, and relationships

Risk Reduction

You can trust that you will receive a quality product on time and that all procedures will be properly handled.

Simplified process

You can check the availability and specifications of AFL MOTORS industrial fans independently or with assistance from our team.

Full support

Regardless of the size of the order, each one is treated with equal commitment. By choosing us, you choose a long-term relationship.

You need a backup plan.

We will back You up!

AFL Motors in numbers

A global manufacturer of industrial fans

3 million

Production capacity

AFL Motors produces up to 3 million industrial fans each year, making us one of the leading companies in the industry.

up to 12 weeks

Delivery time

We focus on quick order processing. Deliveries from our warehouse in Poland – up to 7 days, from China – up to 12 weeks.

99,98%

Order processing

Our main advantage is fast delivery. We always complete orders on time and ensure a smooth process that keeps our customers satisfied and builds their trust.

FAQ

Find answers to common questions.

AFL MOTORS EUROPE G. Perestaj sp. k. is the European Sales and Project Support Office for AFL MOTORS. We are located in Poland, where we have an office and a logistics warehouse with fans “available immediately.” The main office and production plant are near Hangzhou, China.

You can download the current EC and AC fan catalogues from this link or the Support tab on the website.

You can find the declarations of conformity on the website’s Support tab.

AFL fans possess a certificate that verifies compliance with European Union standards (CE). They also hold several awards that attest to their high quality. These include ISO 9001 for Quality Management System, ISO 14001 for Environmental Management System, and ISO 45001 for Occupational Health and Safety Management System. Additionally, they have RoHS certifications, demonstrating their commitment to eco-friendliness, and ErP compliance, which adheres to energy-saving regulations.

Blog

We share expert knowledge and company news in the HVAC-R industry. By exchanging information, we help create a better business environment.

Explore the family of new radial fans for limited installation space

-

Read more

Energy efficiency and the importance of blower technology in air curtains

-

Read more

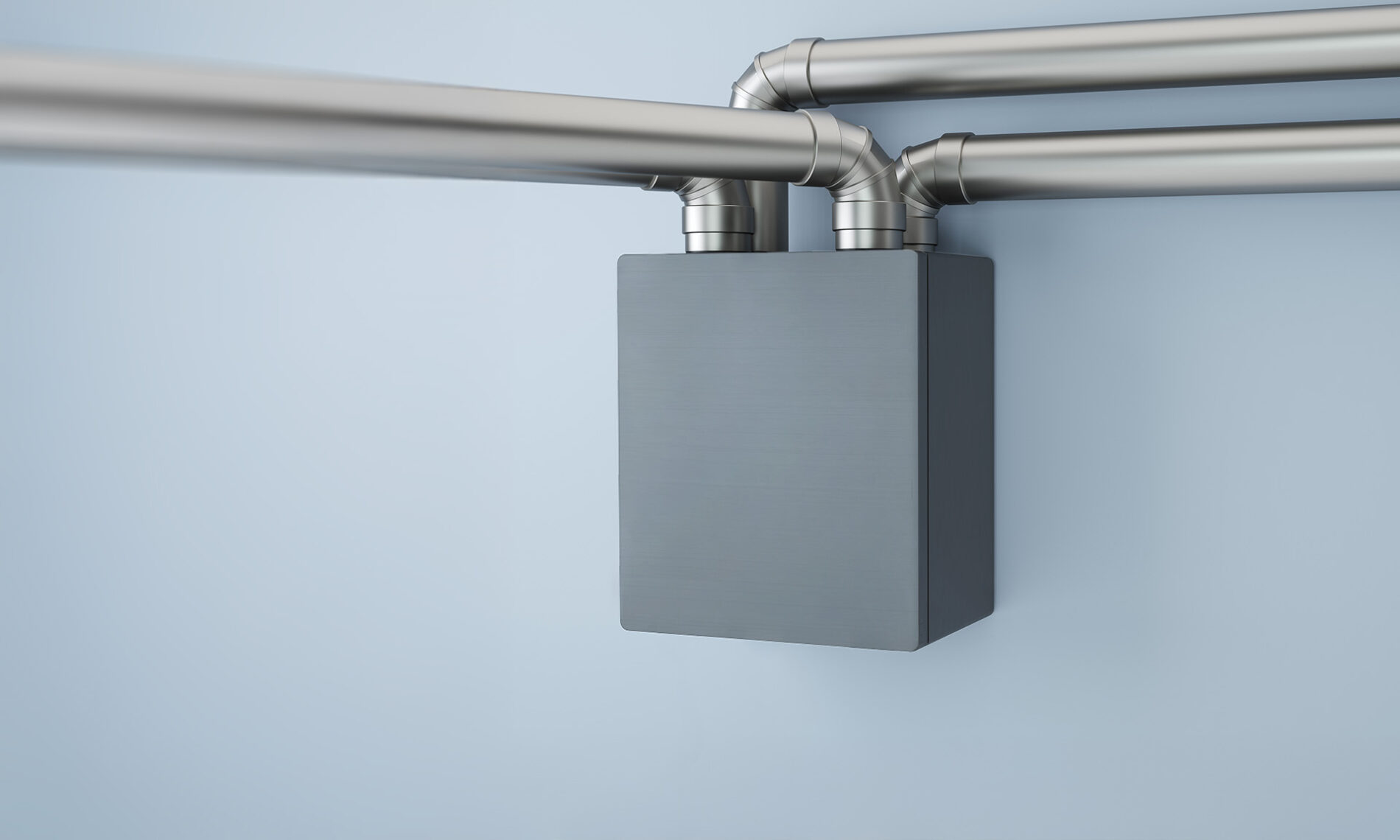

Fans for a heat recovery unit

-

Read more

Why are we the best choice?

AFL Motors is a trusted manufacturer of industrial fans

We blend the strengths of Chinese production with European quality standards, fostering communication and cooperation. Our advantage lies not just in the product but in our overall approach: technical precision, logistical flexibility, and safe, partnership-based relationships with our customers.

Quality and technical compliance

We offer a product along with comprehensive engineering support, ensuring reliability, compliance, and well-crafted solutions.

Effective delivery coordination

Our logistics model relies on a local warehouse, strategic transport planning, and active delivery monitoring to ensure supply continuity and stability within the supply chain.

Safety and partnership

We combine the advantages of global manufacturing alongside a European culture of collaboration, offering customers transparency, quick responses, and comprehensive operational support.

Quality and technical compliance

We understand that catalog data alone is not sufficient. That’s why we provide the option to test entire devices in our laboratory. We evaluate the accuracy of design assumptions, confirm the selection of the fan, and identify areas for optimization. This technical assessment significantly reduces the risk of errors and accelerates product development. Our fans comply with all European Union market requirements; they undergo regular testing in accredited laboratories, and each batch is accompanied by complete technical documentation and compliance certificates.

We ensure quality at every stage of the production process. Each fan undergoes six key control stages- from parameter testing to final inspection, guaranteeing consistency and adherence to technical specifications. If a customer requires a solution that is not available in our catalog, we can design fans according to their specific needs. These products are ready-to-use, fully integrated plug-and-play solutions that fit seamlessly with the end device.

Effective delivery coordination

Our logistics are as precise as our technology. With our warehouse located in Poland, we can fulfill orders quickly and efficiently, without delays. For our regular customers, we reserve batches of goods based on forecasts, creating a safety buffer that eliminates the need for them to store products on-site. We do not impose minimum logistics thresholds, allowing for smaller batches, such as single pallets or fan sets, which simplifies inventory management and minimizes disruptions to cash flow. Impressively, 94% of our deliveries arrive on time. In the event of a potential delay, we proactively inform our customers, enabling them to adjust their production schedules accordingly.

Security and collaboration

As the European representative of a Chinese factory, we offer local services while operating in the same time zone. Our team speaks the language of European business; we are formally registered in the KRS, VIES, and DUNS databases. We invite our customers to visit our factory in China, where they can observe the production process and our quality control system in a transparent manner, without intermediaries.

Our dedicated team of experienced experts provides swift service without unnecessary procedures, demonstrating full commitment to each project. We prioritize partnership, adopt a flexible approach, and offer direct operational support from our office in Poland.

AFL Motors is not just about fans. It is a technology that aligns with the requirements, processes, and values of modern manufacturing companies.