The axial fan is a key element of air heaters. It’s appropriate selection affects the operating parameters, comfort of use, and energy efficiency of the entire device.

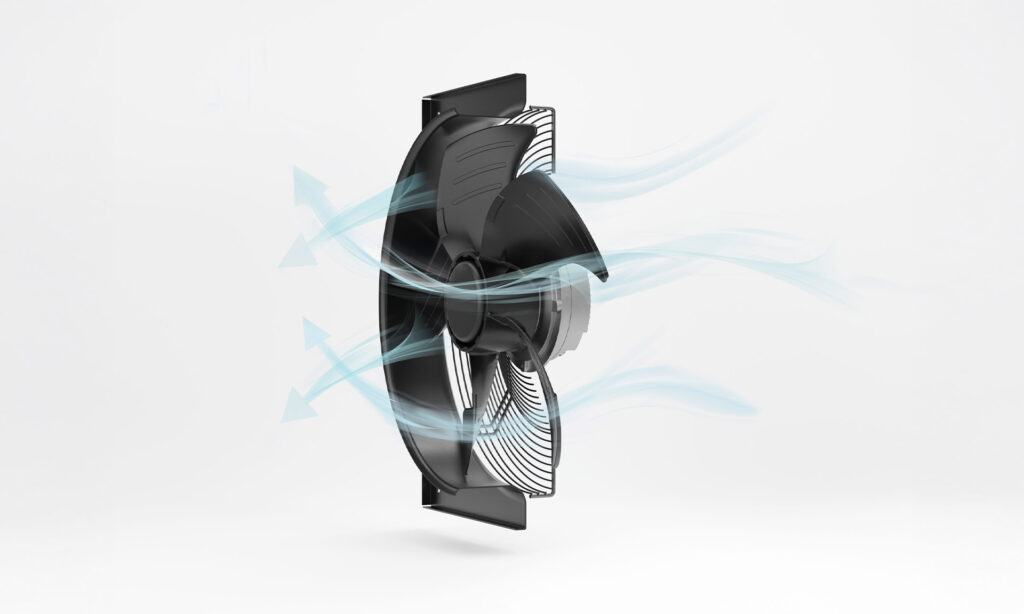

Axial fans are the most commonly used due to the heater’s design, which requires a large air flow with relatively low flow resistance. In these fans, the axis of rotor rotation is parallel to the flow direction of the pumped air stream.

Fans of this type are often offered with a safety grill and a mounting plate with a profiled funnel. AFL’s offer includes axial fans in various construction configurations and airflow directions.

BLOWING AND SUCTION AXIAL FANS

AFL MOTORS offers blowing and suction axial fans:

CONSTRUCTION VERSIONS OF AXIAL FANS

AFL Motors’ offer also includes various design versions:

– the fan itself

– fan with safety grill

– fan with grill and mounting plate integrated with a profiled funnel.

KEY CRITERIA FOR CHOOSING A FAN FOR A FAN HEATER

The key criterion for choosing a fan is the type of motor used. AFL provides axial fans with AC, DC, and EC motors. Fans with AC motors are still commonly used in air heaters. They are relatively inexpensive and widely known. However, additional automation elements, such as frequency converters or voltage regulators, must be used to regulate them.

Optionally, AFL can offer fans with AC motors with a built-in 3-speed control. This often provides sufficient regulation in these types of applications. 3-speed fans have cables leading out to power the selected gear. The fan will operate at specific speeds depending on which gear the power supply voltage is applied to. You can connect the fan to a specific speed or use a simple gear selector to adjust the performance.

ENERGY-SAVING EC AXIAL FANS

Fans with energy-saving EC motors are being used more frequently. These are electronically commutated, brushless motors with built-in electronics, convenient, effective and smooth 0-10V or PWM signal control. Their use allows us to meet increasingly higher energy efficiency requirements and enables smooth efficiency regulation.

EC motors used in heaters are highly efficient even at lower rotational speeds. This results in energy cost savings when using devices with non-constant operating parameters, as the fans can operate efficiently for extended periods of time.

Moreover, thanks to their design, fans with EC motors take up less space and are quieter and lighter than comparable fans with AC motors, along with additional capacity control devices.

THE SHAPE OF THE AXIAL FAN ROTOR BLADES

The rotor blades’ geometry and size greatly influence the airflow and fan pressure. The shape of the impeller blades of an axial fan has a significant impact on its effective operation, efficiency, and generated noise. That is why our R&D department performs hundreds of tests, analyses, and simulations to obtain the best possible results in this area.

FAN NOZZLE

The nozzle in which the fan operates is a crucial aerodynamic component. When the shape of the nozzle is optimally designed and harmonized with the fan rotor, it can greatly improve efficiency and reduce the noise generated by the airflow.

To sum up:

-

- The AFL manufacturer’s offer includes a wide range of axial fan diameters, from 200 to 910 mm, and flow capacities of up to 30,000 m3/h.

-

- AFL axial fans were designed for both effective and comfortable use.

-

- The range includes models made of high-quality components and subassemblies, ensuring quiet and failure-free operation.

The AFL MOTORS EUROPE office will be happy to help you select the right fan to meet the needs of heater manufacturers.